Vat Leaching

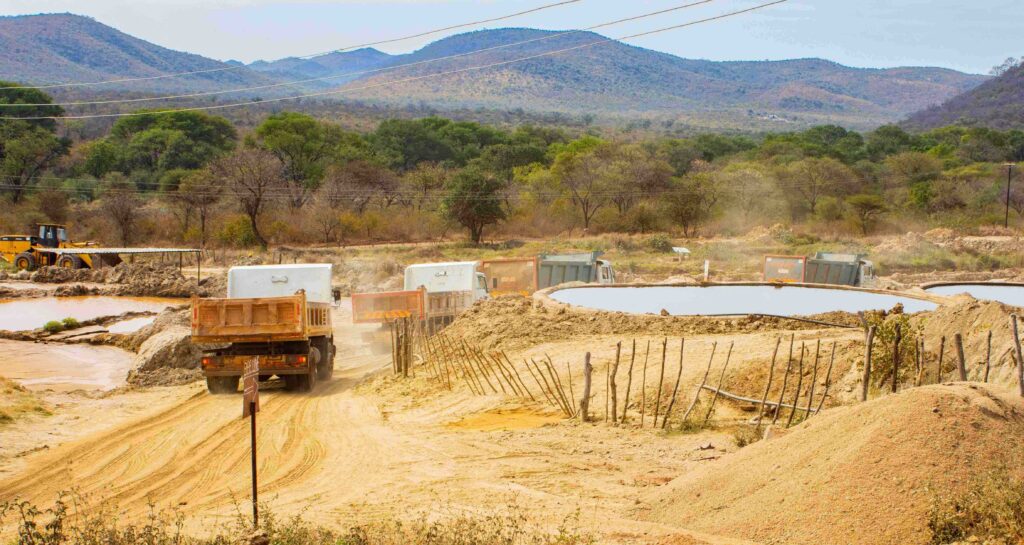

Superb Riches Mining offers advanced vat leaching services, a proven and environmentally responsible method for extracting valuable minerals from ore. Our vat leaching expertise, combined with state-of-the-art equipment and meticulous processes, maximizes the recovery of gold, silver, and other precious metals while minimizing the impact on the surrounding environment. This page provides an overview of our vat leaching services and the benefits of choosing us as your trusted partner.

What is Vat Leaching?

Vat leaching is a hydrometallurgical process used to extract valuable minerals, such as gold, silver, and copper, from ore. It involves the permeation of crushed ore with a leaching solution in large vats or tanks, hence the name “vat leaching.” The leaching solution, often a diluted acidic or alkaline solution, is applied to the ore to dissolve the target minerals.

The vat leaching process typically involves the following steps:

Crushing and Agglomeration: The ore is crushed into smaller particles to increase the surface area for better contact with the leaching solution. Agglomeration may also be performed, where the crushed ore is formed into larger particles or pellets to enhance permeability and leachability.

Leaching Solution Application: The crushed or agglomerated ore is loaded into vats or tanks. The leaching solution is then added to the vat, allowing it to percolate through the ore bed. The leaching solution flows by gravity or is circulated using pumps to ensure uniform contact with the ore.

Leaching and Metal Dissolution: The leaching solution interacts with the ore, dissolving the target minerals into the solution. This process occurs through chemical reactions between the leaching solution and the mineral surfaces, resulting in the transfer of metal ions into the solution.

Solution Collection and Metal Recovery: The pregnant leach solution, containing dissolved metals, is collected at the bottom of the vat. It is then processed through further purification or metal recovery steps, such as precipitation, adsorption, solvent extraction, or electrowinning, depending on the specific metal being targeted.

Solution Recirculation or Disposal: In some cases, the leaching solution may be recirculated through the vat to maximize metal extraction efficiency. Alternatively, if the leaching solution becomes depleted or saturated with metals, it may be treated or disposed of according to environmental regulations.

Vat leaching offers several advantages, including its versatility, scalability, and cost-effectiveness. It can be applied to a wide range of ore types and sizes, and the process can be adjusted to optimize metal recovery and minimize operating costs. However, it requires careful control of factors such as leaching solution composition, temperature, residence time, and agitation to ensure efficient and effective extraction of metals from the ore.

Overall, vat leaching is a widely used technique in the mining industry for the extraction of valuable minerals from ore, providing an efficient and environmentally responsible method for metal recovery.