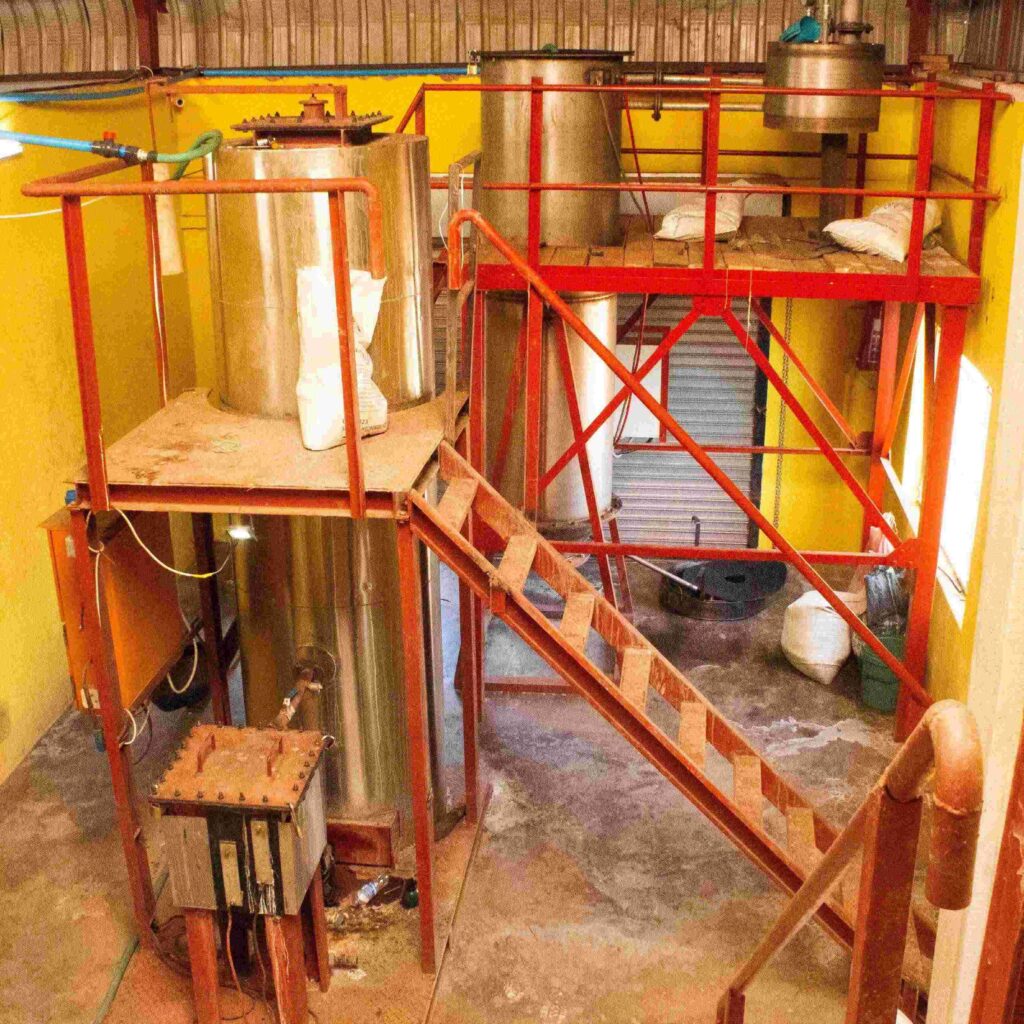

Boiler Plant

We recently opened a gold elution plant in Filabusi business centre which mainly specialises in gold purification processes.

Desorption Electrolysis Equipment

A complete set of system is applied to the treatment of gold-bearing charcoal in the coal pulp plant of gold mines, so that gold can be separated from the gold-bearing charcoal and precipitated into high-grade gold sludge. It consists of electrolysis equipment including desorption column and the electrodeposition tank.

Product Description

In the Desorption electrolysis system, anions that are easily adsorbed by activated carbon are added to the elution

system to replace Au (CN)2-and desorb gold. After loaded carbon elution process, the solid gold is recovered from

pregnant liquid by ionization method.

The high-efficiency, low-consumption elution and electrowinning device is mainly composed of two parts: elution

and electrowinning, and the processes of them are separated. The solvent desorption is in elution column, and the

precious liquid electrolysis is completed in a separate electrolytic cell. The four processes of elution, pregnant liquid

heating, solvent condensation and solvent recovery are concentrated in the elution column. The pregnant liquid

after desorbing the gold-loaded carbon by the solvent vapor is introduced into a separate electrolysis through a

pipeline tor electrolysis to obtain crude gold, which then purified to get product gold.

Features

In the high temperature (1500c) and pressure (0.5MPa), the desorption rate reaches 98%.

Low consumption: the same temperature for desorption, no need of heat-exchanging, working speed is rapid, power consumption is 1/2-1/4 of normal system. Desorption does not require sodium cyanide, which reduces cost and averts pollution.